Equipment

Finamac has the most innovative ice pop equipment in the world:Robopop 2

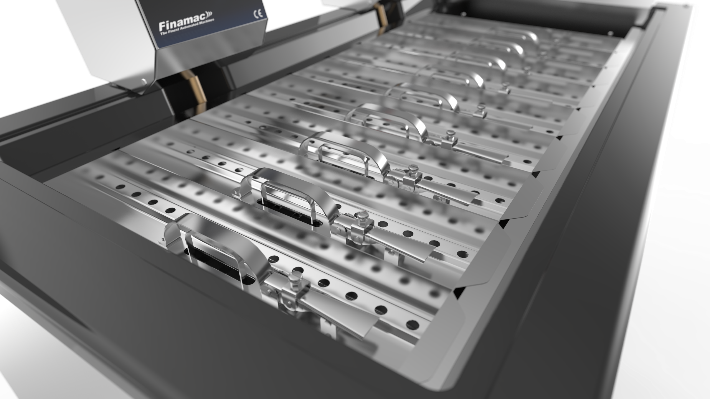

The Robopop integrates the production and unmolding of ice pops in one unit. Filled with the same thermal fluid, the freezing tank is heavily cooled and the unmolding tank is slightly heated to release the popsicles from the mold. The reserve tank is interconnected and serves to automatically control the fluid level on both sides.

Robopop Start

| Technical Details | |||

| Electrical Installation | Start: 220 V, Monophase , 50 Hz or 60 Hz. Ultra: 220 V, Threephase, 50 Hz or 60 Hz. | ||

| Consumption of electricity | Start: 6 KW. Ultra: 10 kW. | ||

| Dimensions | |||

| Crate dimensions | Length x Height x Width (mm). Start: 1350 x 1200 x 1270. Ultra: 1880 x 1200 x 1270. | ||

| Equipment Dimensions | Length x Height x Width (mm). Start: 1165 x 1015 x 975. Ultra: 1780 x 1015 x 975. | ||

| Weight | |||

| Gross Weight with crate | Start: 261 kg. Ultra: 325 kg. | ||

| Net Weight | Start: 170 kg (without fluid and molds) - 243 kg (with fluid and molds). Ultra: 230 kg (without fluid and molds) - 401 kg (with fluid and molds). | ||

| Production | |||

| Production Capacity | Start*: 250 to 350 ice pops per hour** or 130 to 200 paletas per hour***. Ultra*: 700 to 800 ice pops per hour** or 350 to 450 paletas per hour***. | ||

| Condensation | Start: Air. Ultra: Water or air. | ||

Robopop Ultra

| Technical Details | |||

| Electrical Installation | Start: 220 V, Monophase , 50 Hz or 60 Hz. Ultra: 220 V, Threephase, 50 Hz or 60 Hz. | ||

| Consumption of electricity | Start: 6 KW. Ultra: 10 kW. | ||

| Dimensions | |||

| Crate dimensions | Length x Height x Width (mm). Start: 1350 x 1200 x 1270. Ultra: 1880 x 1200 x 1270. | ||

| Equipment Dimensions | Length x Height x Width (mm). Start: 1165 x 1015 x 975. Ultra: 1780 x 1015 x 975. | ||

| Weight | |||

| Gross Weight with crate | Start: 261 kg. Ultra: 325 kg. | ||

| Net Weight | Start: 170 kg (without fluid and molds) - 243 kg (with fluid and molds). Ultra: 230 kg (without fluid and molds) - 401 kg (with fluid and molds). | ||

| Production | |||

| Production Capacity | Start*: 250 to 350 ice pops per hour** or 130 to 200 paletas per hour***. Ultra*: 700 to 800 ice pops per hour** or 350 to 450 paletas per hour***. | ||

| Condensation | Start: Air. Ultra: Water or air. | ||

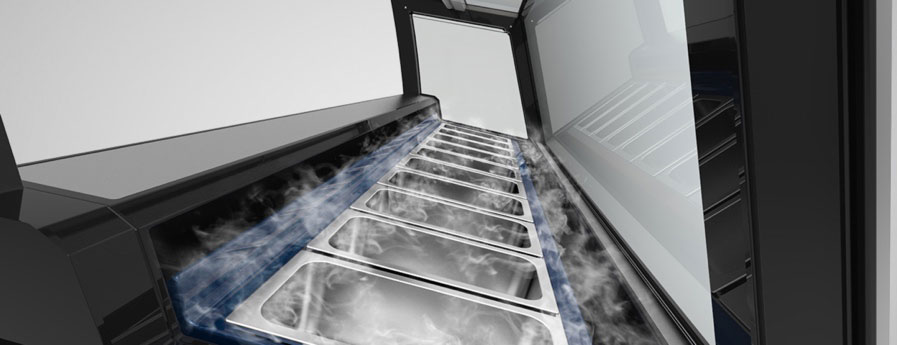

Turbo

The Turbo line are semi-automated machines for producing popsicles. These easy to operate machines occupy 60% less space than that of conventional equipment, have an excellent production time rating and quick temperature recovery. The Turbo line by Finamac incorporates the latest technology in popsicle production but its simplicity makes it the perfect machine for any entry-level business.

Turbo 8

Turbo 25

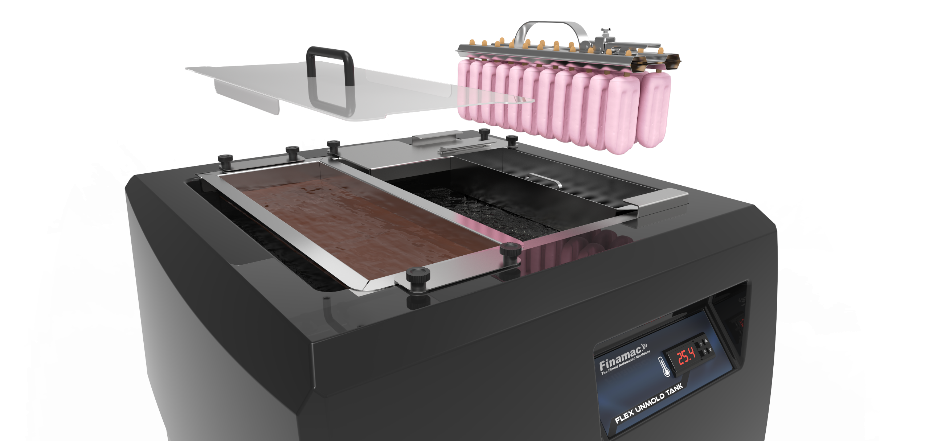

Flex Unmold Tank

The Flex Unmold Tank is essential for removing the ice pops from their molds after the freezing process is complete. The molds are placed in temperature controlled warm water for a few seconds and the ice pops are removed from the mold. Additional features include the ability to place vats of melted chocolate in order to dip popsicles once they are removed from their molds.

Mixers

The Flex Mixer and Mixer 15 have been developed to incorporate air in the mixture and decrease the particle size of the ingredients in the mixture. The aeration of the mixture increases the efficiency of the freezing process and profitability.

Flex Mixer

The Flex Mixer comes in 2 vat sizes: 15-liter or 25-liter. The mixer allows the user to pour the product directly into the molds/pitcher via its tap.

Mixer 15

The Mixer 15 utilizes its 8-liter rectangular recipient for homogeneous mixing. The rectangular recipient is easily removable and easy to operate.

Sealer

Manual sealer for plastic popsicle bags. Sealer has a foot pedal for easy operation and stamps the date of production on the seal. Works on both 110v or 220v.

Pack 5000

The Pack 5000 is specially designed for the continuous packaging of popsicles. The unit is capable of packaging 5,000 to 12,000 units per hour, depending on the type of product being packed.

Accessories

Aligners and Molds

Molds and aligners for popsicles are available with 22, 26 or 28 cavities. Review our Molds Spec Sheet below for mold and aligner models.

Display Cases

The inclined position of the Finamac Display Cases allows your customers to see your product from a distance. This design is exclusive to Finamac and prevents your product from being “hidden” like a traditional ice cream display.

Features of Finamac Display Cases:

- Special tempered glass is anti-fog and enables the product to be seen clearly.

- Internal cold and dry air curtain keeps the temperature uniform and prevents ice crystals from forming.

- Internal lighting is located above the displayed products.

- Internal tank, where containers are placed, can be removed for easy internal cleaning.

- Easy to transport; comes with lockable casters.

Elegance

Vista

Water Cooling Tower

The Water Cooling Towers provide maximum performance to your popsicle machines. The water tower provides a quite work environment as the ventilation is now outdoors. The water towers also allow installation of multiple devices on the same tower.

Packages

Robopop Popsicle Package includes the following:

- Robopop 2

- Flex Mixer 15L

- Sealer

- Delivery

- Installation

- Training

- 1 year warranty

Turbo Popsicle Package includes the following:

- Turbo 8

- Flex Unmold Tank

- Flex Mixer 15L

- Sealer

- Delivery

- Installation

- Training

- 1 year warranty